We understand our industry has problems

Buying new heavy equipment, if you can source it when you need it, can be expensive.

And buying used heavy equipment can be risky if you can’t trust the company you are buying from.

In today’s construction environment, equipment failure and missed deadlines can be catastrophic.

You need a trustworthy partner that can be your heavy equipment solution on time and at a price you can afford – and with the service you deserve!

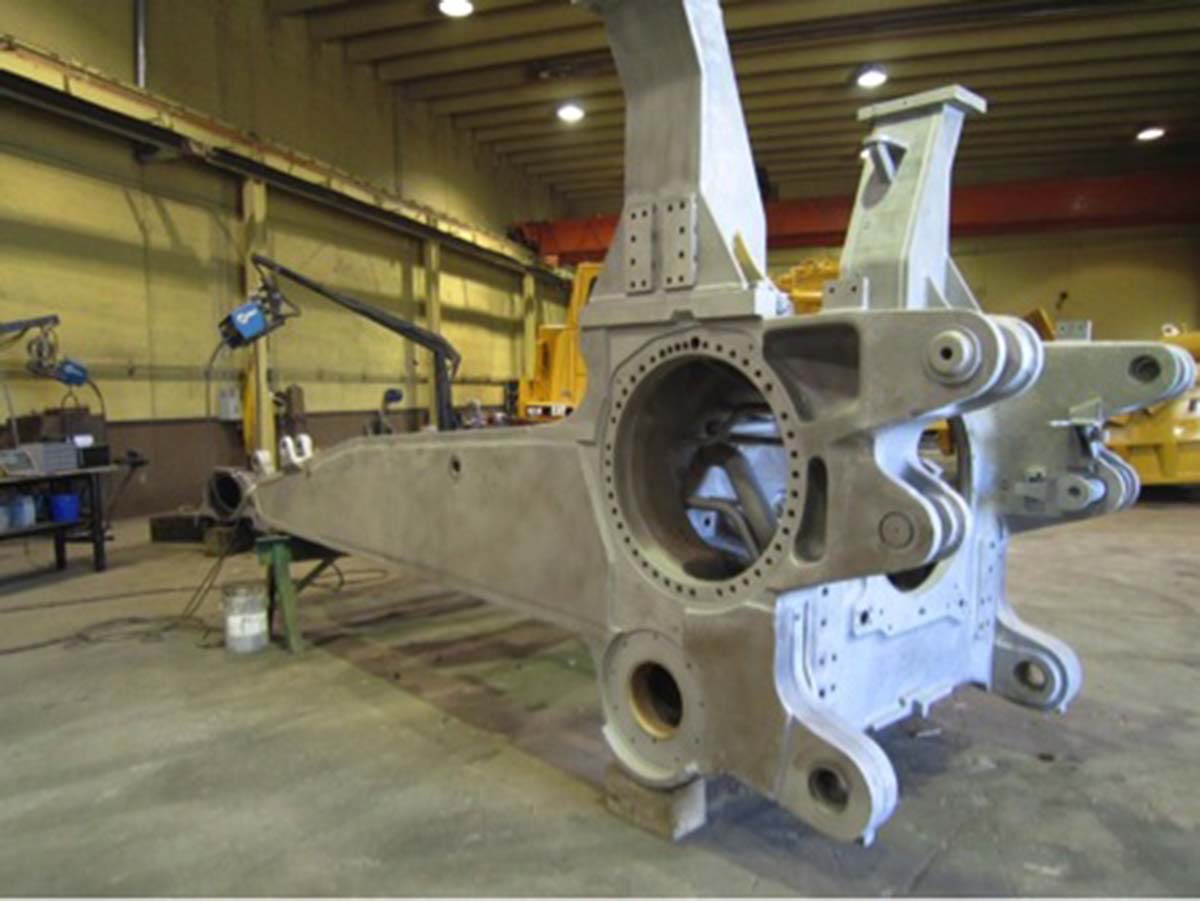

The founders of Evans Equipment began working at Dean Machinery, the local Caterpillar Dealership, where they recognized a need for a reliable and trustworthy company that provides quality used machinery to the farm power industry. These men began rebuilding machines like D6 9U series and D7 17A series dozers from the bare frame up.

The Evans Equipment quality mind set has not changed in over fifty years of doing business. They believe Evans Equipment, Inc. has been able to endure in business this long because their customers have benefited from acquiring a valuable asset in our rebuilt machines. Evans Equipment, Inc. has not only continued to provide machines for the farm power industry but also provides quality heavy mining and construction machinery all over the world. After 50 years in the used equipment business the philosophy of providing the very best rebuilt equipment has remained and has become a source of pride for every employee since day one.

SQ FT of Covered Space

SQ FT of Shop Space

Buy like-new used Caterpillar & other heavy equipment in 3 simple steps

While we are most well-known for a company that sells high-quality used machines, we buy late model, low hour machines as well. Please keep us in mind when you’re selling core machinery and low hour equipment!

Learn more about us

Evans Equipment Inc. was founded back in 1965 by Tom Evans, the father of current owners Bryce & Brad Evans. While he initially started out as a territory salesman for Caterpillar, he quickly noticed that there was a need in the market for quality pre-owned or used equipment. He made the crucial decision to leave Caterpillar and begin his own company with the help of a few close partners.

Learn more about our equipment

Our most well known branch of business is obtaining heavy equipment cores and rebuilding them to new factory specifications. Not only do we offer the highest quality rebuilt machines, we also provide the highest quality late model low hour equipment.

Earth Moving & Support Mining Equipment

Equipment in this category can include things like:

They asked and we answered

Recent News & Blog Posts

February 28, 2017

December 30, 2016

December 9, 2016

Equipment

401 N Outer Rd

Concordia, MO 64020

(660) 463-2204